Mask Data Preparation

As the cost of a complete mask set has dramatically increased and now represents a significant part of the overall project cost. Thus, it is critical for design teams, mask data preparation teams, and mask shops to implement a robust and repeatable Mask Data Preparation flow. Doing so, it increases the productivity of mask set creation and removes any risk of error.

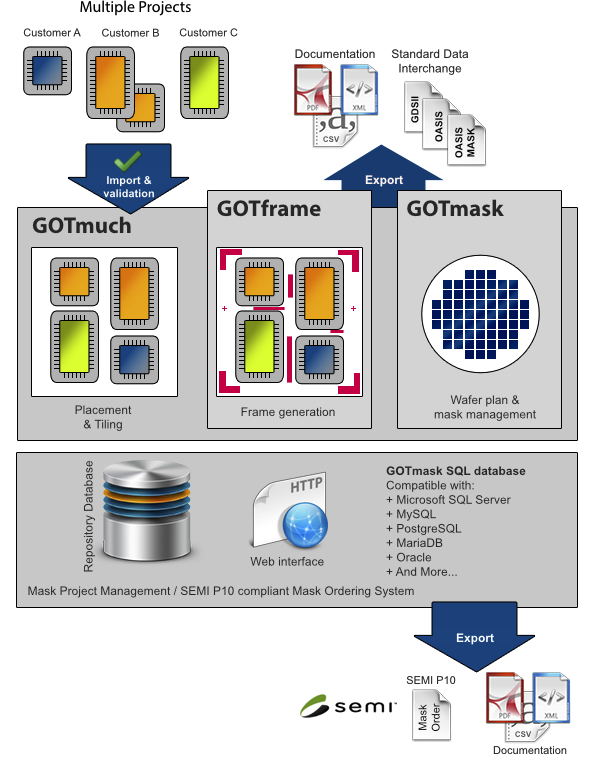

XYALIS offers a suite of tightly integrated state-of-the-art Mask Data Preparation modules. They automate the repetitive and time consuming tasks between design and fracturing:

- Generation of Multi Project Wafers (MPW) or shuttles with GOTmuch. It’s an automated placement tool dedicated to maximizing silicon usage and minimizing saw lines when assembling heterogeneous chips,

- Generation of complex reticles with GOTframe. It’s an automated tool for inserting manufacturing items between chips and inside scribe lines, according to reusable process rules,

- Intuitive mask set creation with GOTmask, supporting Multi-Layer Reticles (MLR), optimized 1X flow, and wafer map optimization.

Built around a powerful dedicated graphical editor and a shared data format, XYALIS MDP solution handles standard layout and job deck formats: GDSII, OASIS ®, MEBES. Each module can be run through the common graphical user interface or on the command line for automatic processing and easy inclusion in an existing flow.

GOTframe

Frame assembly editor

- Reusable frame description file

- Automated item placement

- Field ...

GOTcross

Multi Project Wafer Placement

- Handles production requirements

- Handles manufacturing requirements

- Customized ...

GOTmask

Mask Set Editor

- Automatic generation of titles and barcodes

- Includes a library ...